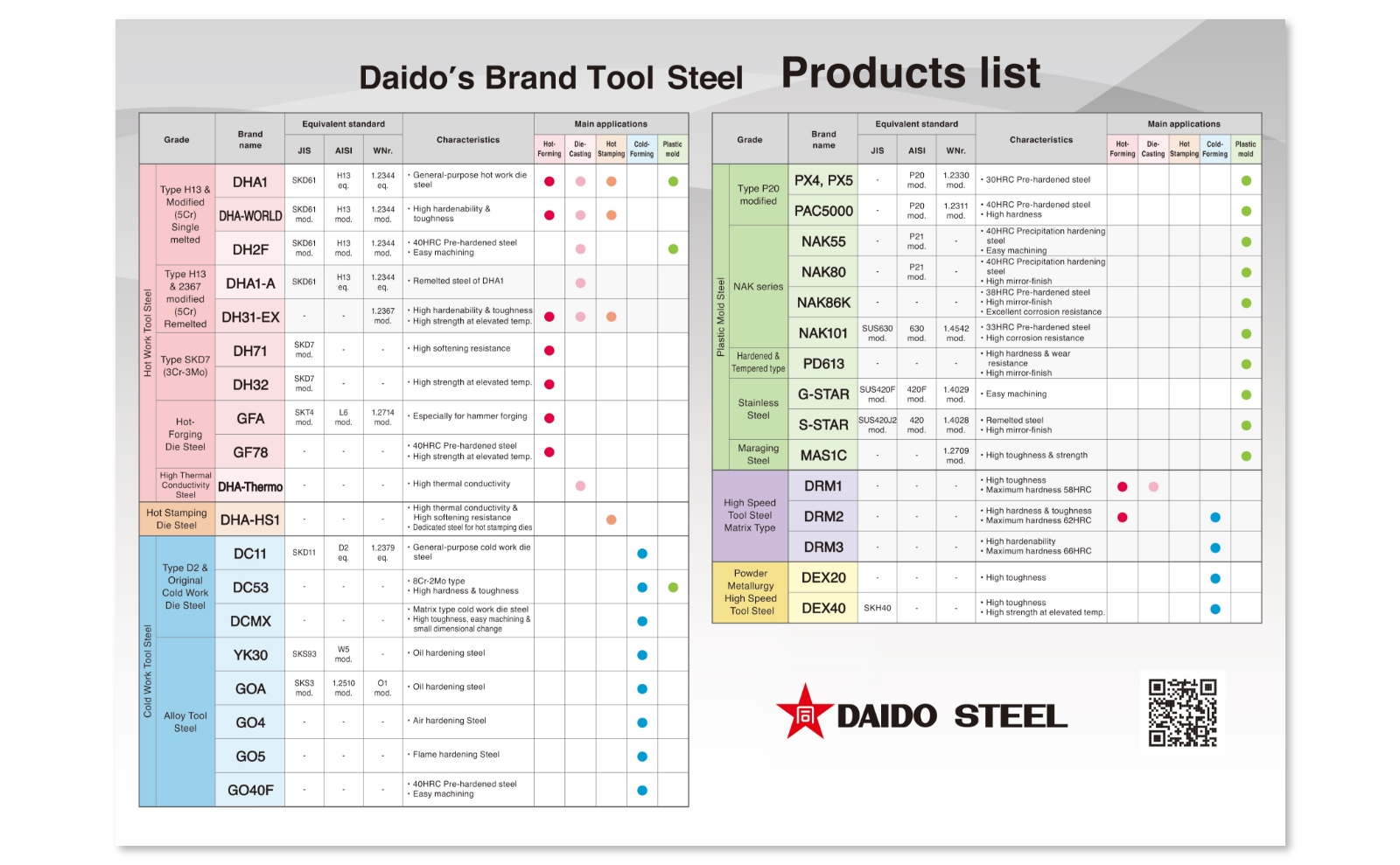

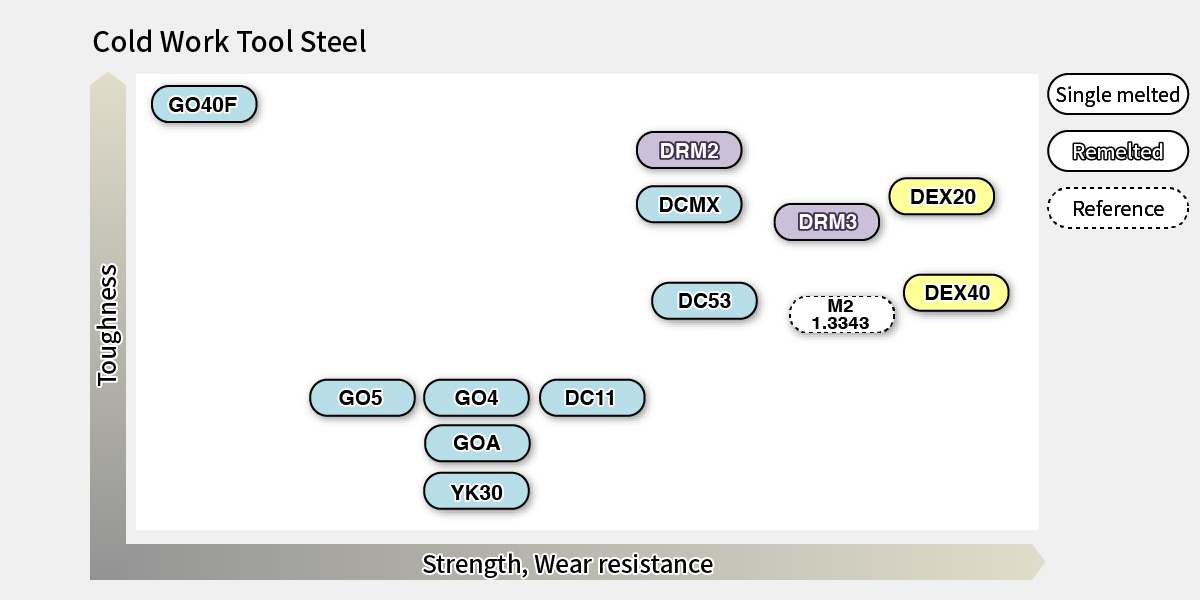

Cold Work Tool Steel

Daido Steel's tool steels lineup for cold stamping and forging includes D2, matrix-high-speed steel, and original steel grades with high hardness and toughness.

Our products contribute to the prevention of wear, chipping and other issues that may happen in cold stamping for high tensile strength steel sheets and thick steel sheets. It is also applicable to cold working tools such as rolls and blades.

Conceptual diagram

Products list

For the latest physical property data, please see "Physical Properties“.

Values listed in the brochure may differ.

Technical Data

| No. | Title | Publication / Source | Volume & page | Read the document |

| S03e | The application of DCMX (No. SD1901) | - | - | Open PDF file |

| G01 | 1C-1Si-8Cr-2Mo系冷間工具鋼の高温焼戻し硬さと2次硬化挙動について | 大同特殊鋼技報「電気製鋼」 | 1989年 60巻 4号 p.311-323 | Go to J-STAGE site |

| G02 | 1C-1Si-8Cr-2Mo鋼の靱性に及ぼす残留オーステナイトの影響 | 大同特殊鋼技報「電気製鋼」 | 1993年 64巻 3号 p.140-151 | Go to J-STAGE site |

| G03 | 1C-8Cr系高温焼戻し冷間工具鋼の経時寸法変化におよぼす残留オーステナイト安定化の影響 | 大同特殊鋼技報「電気製鋼」 | 2000年 71巻 2号 p.141-148 | Go to J-STAGE site |

| G04 | 冷間工具鋼の疲労強度に及ぼす一次炭化物分布の影響 | 大同特殊鋼技報「電気製鋼」 | 2005年 76巻 4号 p.249-257 | Go to J-STAGE site |

| G05 | 冷間ダイス鋼の熱処理変寸の異方性に及ぼす晶出炭化物の影響 | 大同特殊鋼技報「電気製鋼」 | 2007年 78巻 4号 p.289-290 | Go to J-STAGE site |

| G06 | 熱処理寸法の制御が容易なマトリックス冷間ダイス鋼 DCMX | 大同特殊鋼技報「電気製鋼」 | 2010年 81巻 1号 p.53-60 | Go to DENKI-SEIKO page |

| (G06e) | A New Type Cold Work Die Steel with Isotropy of Dimensional Change “DCMX" (No. SD2006) |

Source: DENKI-SEIKO (Electric Furnace Steel) |

2010, Vol.81, No.1, p.53-60 | Open PDF file |

| L01 | 高硬度・高靭性マトリックスハイスDRM鋼の開発 | 大同特殊鋼技報「電気製鋼」 | 2005年 76巻 4号 p.279-286 | Go to J-STAGE site |

| (L01e) |

The Development of High Hardness and Toughness Matrix Type High Speed Tool Steels “DRM” (No. SD2108) |

Source: DENKI-SEIKO (Electric Furnace Steel) |

2005, Vol.76, No.4, p.279-286 | Open PDF file |

| L02 | 金型用マトリックスハイスDRM鋼の実用事例 | 大同特殊鋼技報「電気製鋼」 | 2007年 78巻 4号 p.353-360 | Go to J-STAGE site |

Related Documents

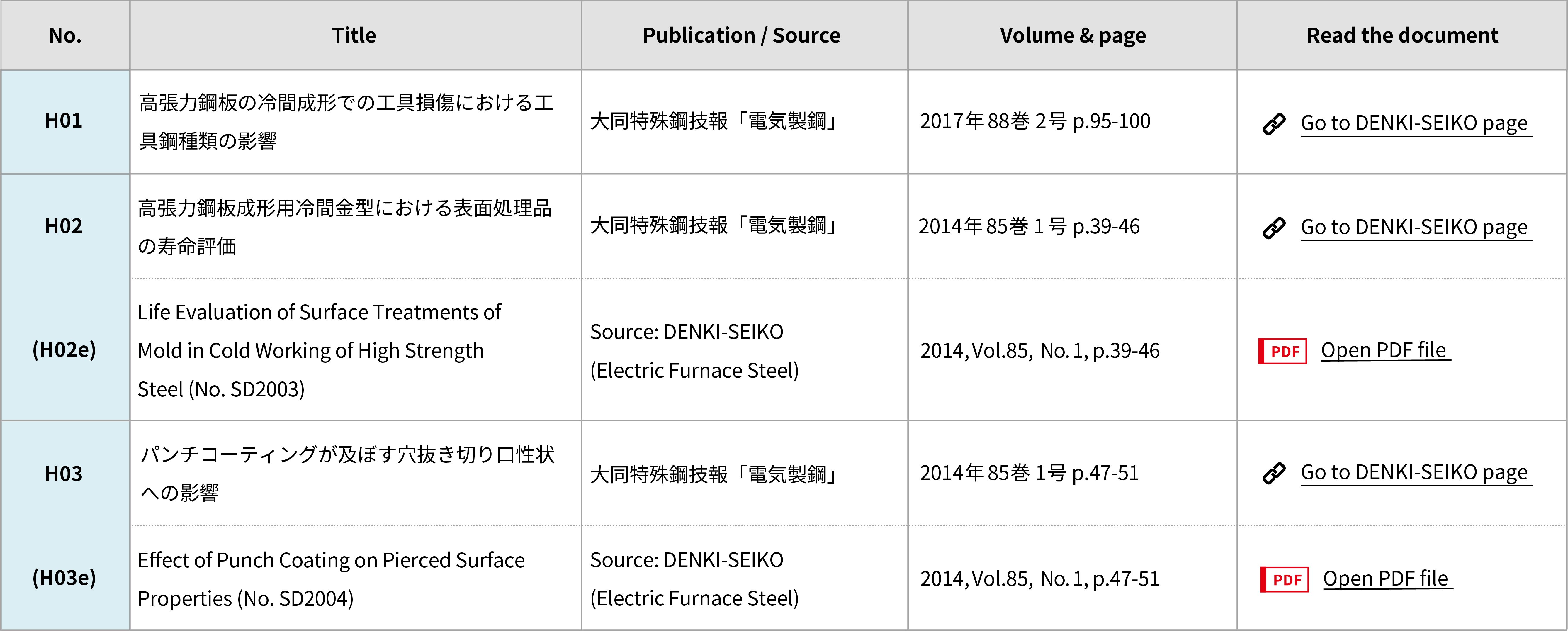

| No. | Title | Publication / Source | Volume & page | Read the document |

| H01 | 高張力鋼板の冷間成形での工具損傷における工具鋼種類の影響 | 大同特殊鋼技報「電気製鋼」 | 2017年 88巻 2号 p.95-100 | Go to DENKI-SEIKO page |

| H02 | 高張力鋼板成形用冷間金型における表面処理品の寿命評価 | 大同特殊鋼技報「電気製鋼」 | 2014年 85巻 1号 p.39-46 | Go to DENKI-SEIKO page |

| (H02e) |

Life Evaluation of Surface Treatments of Mold in Cold Working of High Strength Steel (No. SD2003) |

Source: DENKI-SEIKO (Electric Furnace Steel) |

2014, Vol.85, No.1, p.39-46 | Open PDF file |

| H03 | パンチコーティングが及ぼす穴抜き切り口性状への影響 | 大同特殊鋼技報「電気製鋼」 | 2014年 85巻 1号 p.47-51 | Go to DENKI-SEIKO page |

| (H03e) |

Effect of Punch Coating on Pierced Surface Properties (No. SD2004) |

Source: DENKI-SEIKO (Electric Furnace Steel) |

2014, Vol.85, No.1, p.47-51 | Open PDF file |